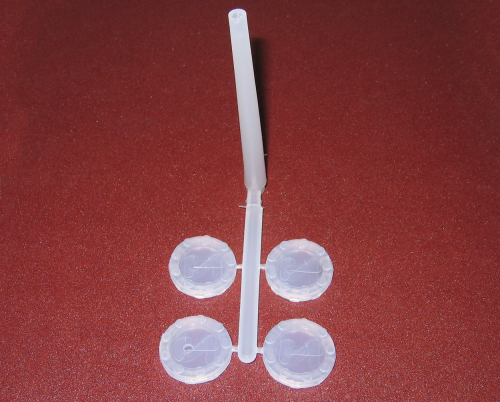

Injecting both molds went well and produced great parts. The first shot of the checkers didn't completely fill the mold, so we filed the gate a little larger and then it filled well. The checkerboard would also sometimes stick to the deeper half of the mold, so a larger draft angle should probably be used in the future. Also, the bottom edge of the board pieces showed some leaking out of the plastic between the molds which was just cut off along with the gates.

The checkers would come out cleanly with the sprue and were then easily cut off and good to go. Here you can faintly see the "1" etched on the top surfaces.